High-end potato snowflakes

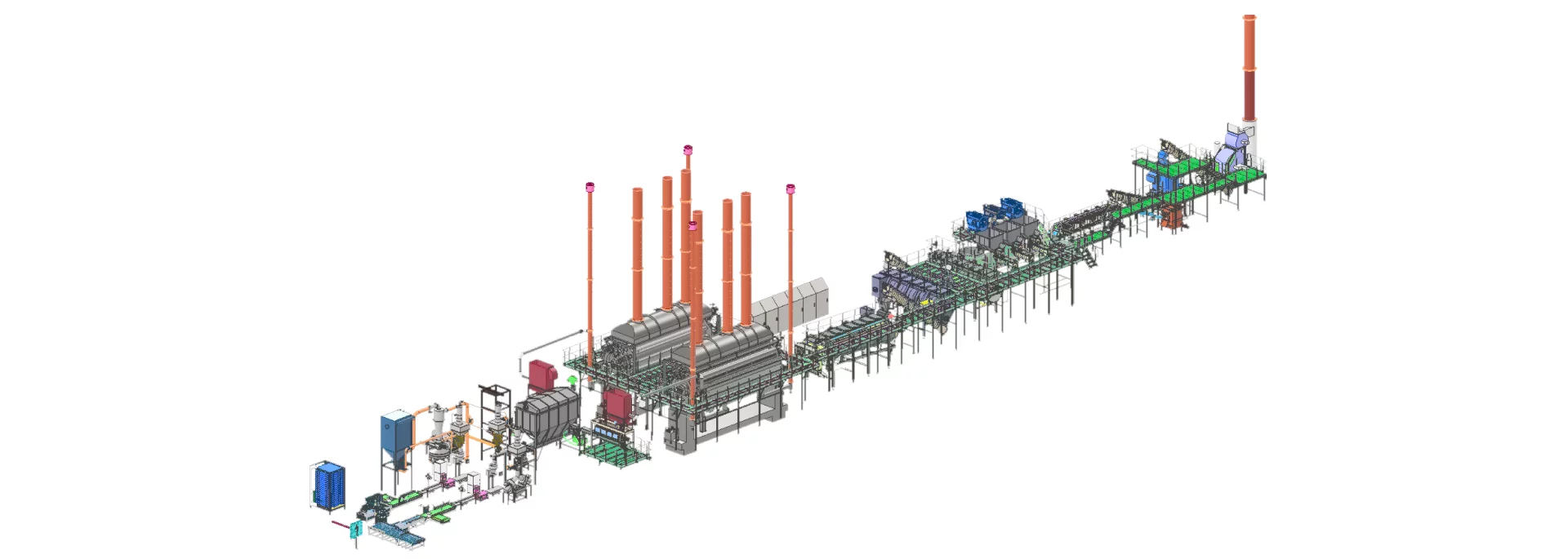

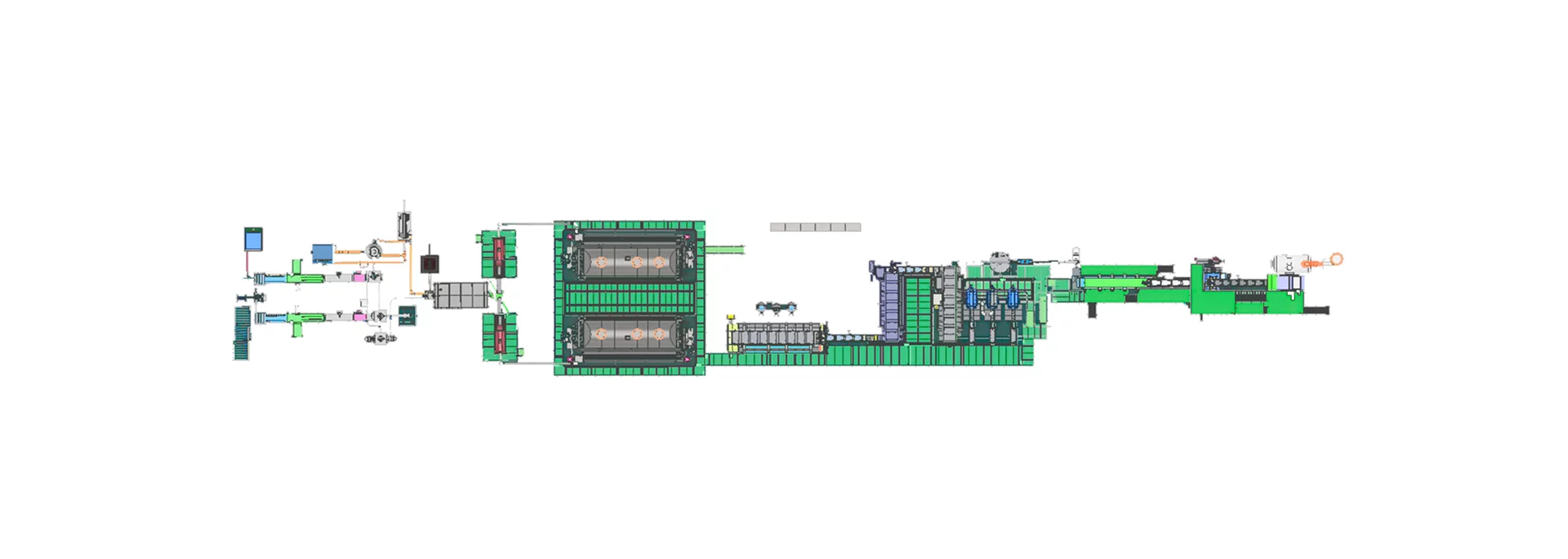

Full powder line

Performance Advantages:

flow path

Whole powder, whole process production line

Raw material feeding

Fresh potatoes are conveyed to silos to ensure a continuous and stable feed.

Silo

Store the finished potato flour to ensure continuity in the packaging process.

Wash and remove stones

Dirt and impurities are removed from the surface of potatoes by means of a cleaning device, and foreign objects such as stones are removed at the same time.

Steam peeling

Use high-temperature steam to quickly remove the skin of the potatoes and keep the flesh intact.

Peel with a roller or brush

Remove any remaining skin further to ensure that the tubers are clean.

Wet washing machine

Wash the peeled potatoes thoroughly to ensure that no impurities remain.

Visual inspection tape

Manual or automatic inspection to remove defective potato chunks to ensure product quality.

slice

Cut the potatoes into thin and uniform slices for easier processing.

Blanching

Short-term heat treatment, inhibits enzyme activity, and maintains the color and texture of potato chips.

cooling

Quickly cool the blanched chips to prevent overcooking.

Cooking

Cook the chips thoroughly to make sure they are cooked and ready to mash.

additive

According to the needs of the product, add the appropriate amount of stabilizer or antioxidant to improve the quality of the product.

Mash the mud

Mash the cooked potato chips into an even puree.

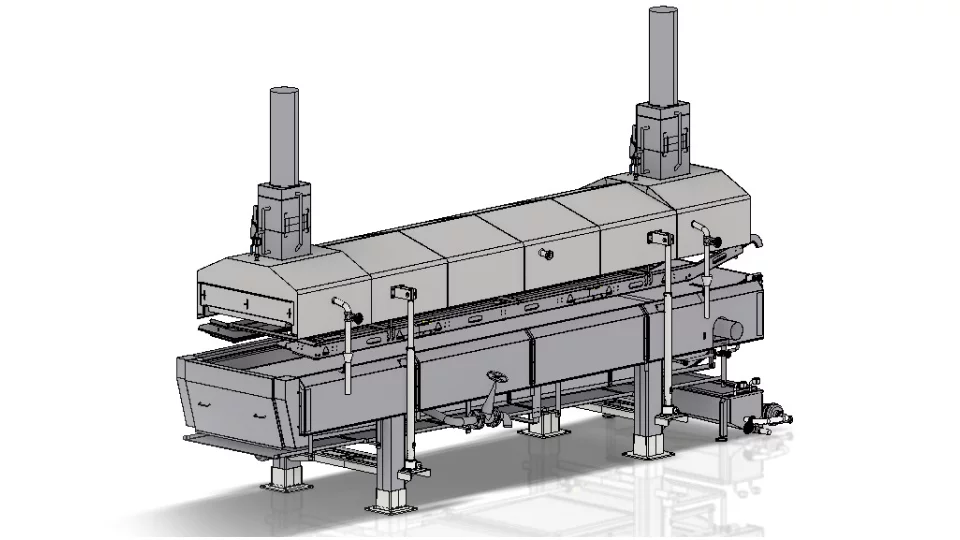

Drum dryer

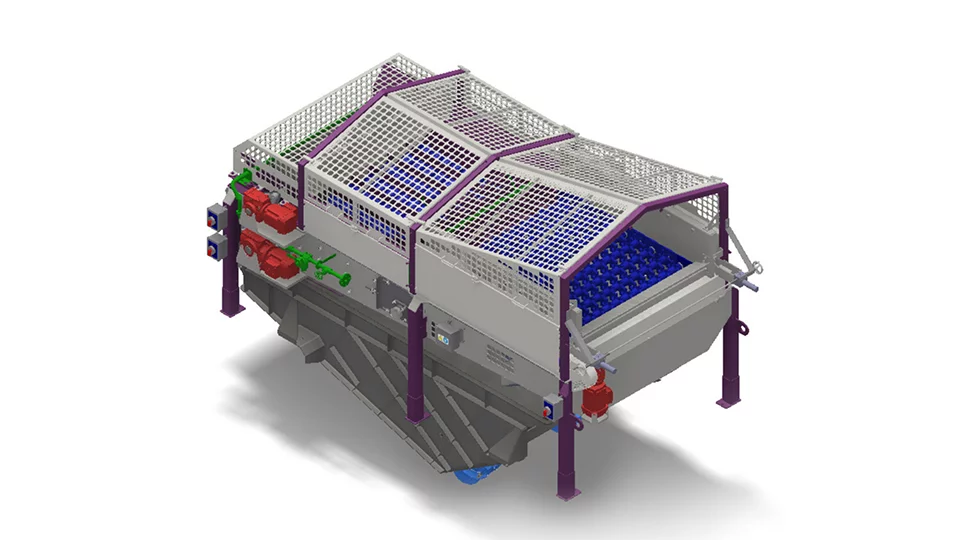

The mashed potatoes are dried in a tumble dryer to make potato flour chips.

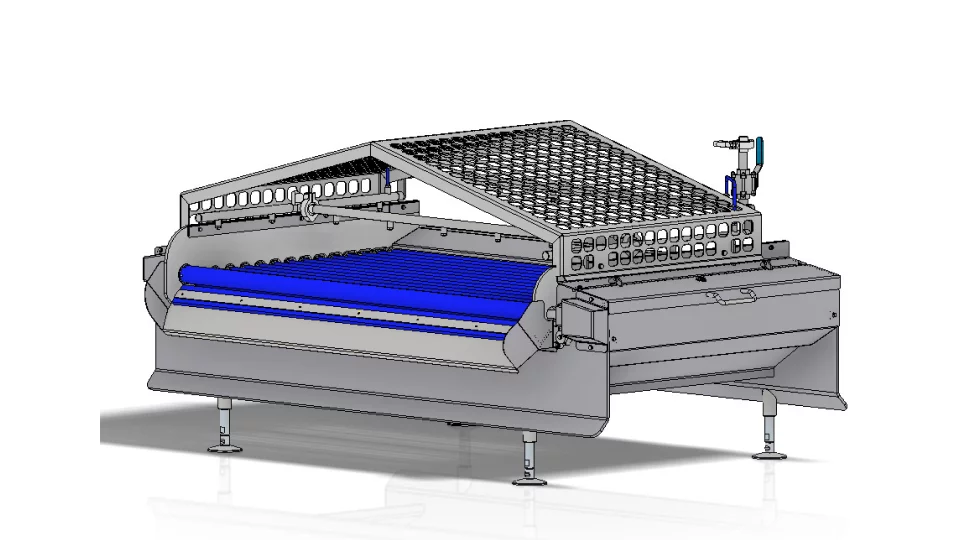

Remove moisture and blemishes

Further drying and rejection of defective potato flour flakes ensures product quality.

smash

Crush the potato flour flakes into fine potato flour.

Silo

Store the finished potato flour to ensure continuity in the packaging process.

products

Potato flour is weighed and packaged to ensure tightness and shelf life.

Machines on this processing line

Whether you're new to food processing equipment or looking for a more efficient and reliable overall solution, WSBG always puts the customer at the center and listens to every detail. From stand-alone customization to whole line planning, we not only provide equipment, but also provide landing and vision.

Fill in the information below and one of our professional consultants will contact you as soon as possible to turn your ideas into results.